Carbon Nanotube Technology and Applications

- Overview

Carbon nanotube (CNT) technology uses cylindrical carbon molecules (rolled graphene) with extraordinary strength, conductivity, and thermal properties for applications in lighter, stronger composites, advanced electronics, better batteries, water filtration, and medicine (drug delivery).

These nanoscale materials reinforce structural components, enhance energy storage, create sensors, and even serve in biomedical fields, promising revolution in aerospace, automotive, energy, and healthcare sectors.

A. Key Properties of Carbon Nanotubes:

- Strength: 100 times stronger than steel but much lighter.

- Electrical Conductivity: Can conduct electricity better than copper.

- Thermal Conductivity: Efficient heat conductors.

- High Surface Area: Useful for filtration and catalysis.

- Tunable Properties: Can be metallic or semiconducting depending on structure.

B. Potential Applications:

1. Materials & Composites:

- Reinforcing polymers, metals, and ceramics for aerospace, automotive parts (tires, chassis), and sports equipment (rackets, bikes).

- Wear-resistant coatings and lightweight structural components.

2. Electronics & Energy:

- Batteries and supercapacitors for improved life and power.

- Field-effect transistors, sensors, and transparent conductive films.

- Electromagnetic shielding.

3. Biomedical:

- Targeted drug delivery systems.

- Biosensors and personalized medicine.

4. Environmental:

- Water purification filters for removing salts, chemicals, and bacteria.

- Catalyst supports for environmental remediation.

5. Other:

- Space elevator tethers (proposed).

- Conductive paper, inks, and advanced textiles.

C. How it Works:

CNTs are integrated into materials, leveraging their incredible strength-to-weight ratio and conductivity, often replacing or complementing traditional materials like carbon fiber.

Their nanoscale structure allows for precise manipulation to create materials with tailored properties for specific high-performance applications.

- How are Carbon Nanotubes Made?

Carbon nanotubes (CNTs) are made using high-temperature methods like Arc Discharge and Laser Ablation, or the more scalable Chemical Vapor Deposition (CVD), which involves decomposing carbon-containing gases (like methane or acetylene) over a metal catalyst on a heated substrate to grow nanotubes.

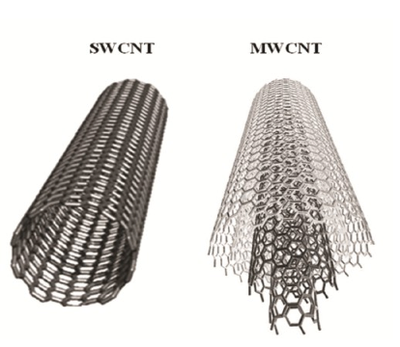

Each method involves vaporizing carbon and allowing it to condense into tubular structures, often requiring catalysts to control size, chirality, and wall structure (single-walled vs. multi-walled).

1. Chemical Vapor Deposition (CVD)

- Process: A substrate coated with metal catalyst nanoparticles (like iron, cobalt, nickel) is heated in a furnace (700°C+). A carbon-rich gas (e.g., methane, ethylene, acetylene) is flowed in, decomposes, and deposits carbon atoms onto the catalyst, which self-assemble into nanotubes.

- Pros: Most common, scalable, cost-effective, allows control over CNT properties by changing catalysts and conditions.

- Cons: May produce some impurities, requiring purification.

2. Arc Discharge:

- Process: An electric arc vaporizes graphite electrodes in a chamber filled with inert gas, creating carbon vapor that forms nanotubes as it cools. Adding a metal catalyst to the anode produces single-walled CNTs.

- Pros: Produces very pure, defect-free nanotubes; relatively simple equipment.

- Cons: Difficult to scale for large quantities, nanotubes are often mixed with soot and need cleaning.

3. Laser Ablation:

- Process: A powerful laser vaporizes a graphite target (often mixed with catalysts) in a furnace, creating a carbon plume that condenses into CNTs.

- Pros: High-quality, well-defined nanotubes, can operate at lower temperatures.

- Cons: More expensive and less scalable than CVD.

4. Other Methods:

- High-Pressure Carbon Monoxide (HiPCO): Disproportionates CO into CNTs.

- Household Ingredients (Research): MIT found sodium-containing items (like baking soda, salt) could catalyze CNT growth at lower temperatures, potentially on polymers.

[More to come ...]