MEMS and NEMS Devices

- Overview

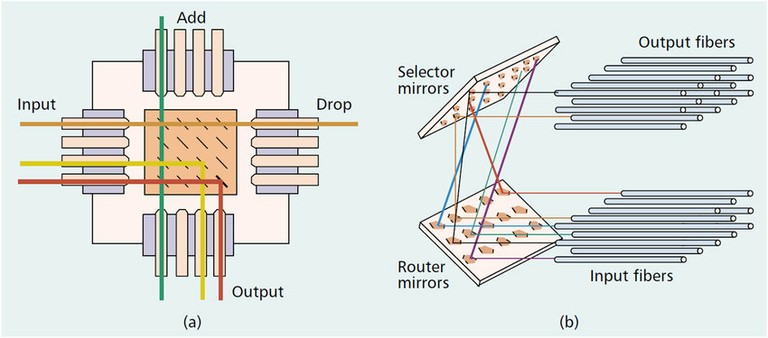

MEMS (Microelectromechanical systems) are miniaturized devices with dimensions in the micron range that integrate mechanical and electronic components, used in applications like accelerometers for airbags and inkjet nozzles.

NEMS (Nanoelectromechanical systems) are similar but scaled to the nanoscale, enabling unprecedented capabilities such as weighing single molecules, developing high-frequency resonators, and manipulating individual human cells.

The fabrication of both MEMS and NEMS relies on microfabrication techniques, but NEMS also takes advantage of altered physical phenomena at the nanoscale, like quantum forces, to create new engineering opportunities.

A. MEMS (Microelectromechanical Systems):

1. Definition:

- Tiny devices that integrate mechanical and electronic components, usually with characteristic lengths from a few millimeters down to one micron (10⁻⁶ meters).

2. Fabrication:

- Made using microelectronics fabrication techniques, such as depositing thin layers of materials and then selectively etching them away to create microscopic structures.

3. Applications:

Found in everyday technology, including:

- Automotive: Accelerometers for airbag deployment.

- Printers: Inkjet printer nozzles.

- Sensors: Pressure sensors.

- Bioengineering: Microfluidic devices for chemical separation and analysis.

- MEMS scaled to the nanoscale (submicron dimensions), allowing for even smaller and more sensitive devices.

2. Advantages:

- At the nanoscale, new forces and interactions emerge, such as quantum friction and quantum elasticity, providing new capabilities beyond what is possible with MEMS.

3. Applications:

- Mass Detection: Weighing single molecules with incredible precision.

- High-Frequency Resonators: Operating at frequencies up to a billion cycles per second.

- Ultra-Fast Switches: Creating low-power, high-speed switches.

- Cellular Manipulation: Integrated microfluidic devices that can separate, manipulate, and analyze individual human cells.

[More to come ...]